Open-pit mining, also known as surface mining, is a technique utilised to extract minerals and ores found close to the earth’s surface. Unlike underground mining, this method involves the removal of large quantities of soil and rock to access the valuable resources underneath.

The following sections will explore the scientific principles underlying the management of open-pit mines, focusing on the critical role of batters and outlining Erizon’s advanced solutions for erosion control and site rehabilitation.

What Is Open Pit Mining?

Open-pit mining is a method of extracting minerals and ores from the Earth through the creation of an open pit or burrow. This mining technique is used when the desired resource is located near the surface of the Earth or when it is economically more feasible to extract it through this method rather than through underground mining.

The process involves digging large open holes in the ground, as opposed to tunnelling or shaft mining. It requires the removal of vegetation, topsoil and layers of bedrock to reach ore deposits. The efficiency of open-pit mining, along with its ability to extract materials that might be too difficult to mine in other ways, makes it a preferred choice in many situations.

Structure of the Mine Site

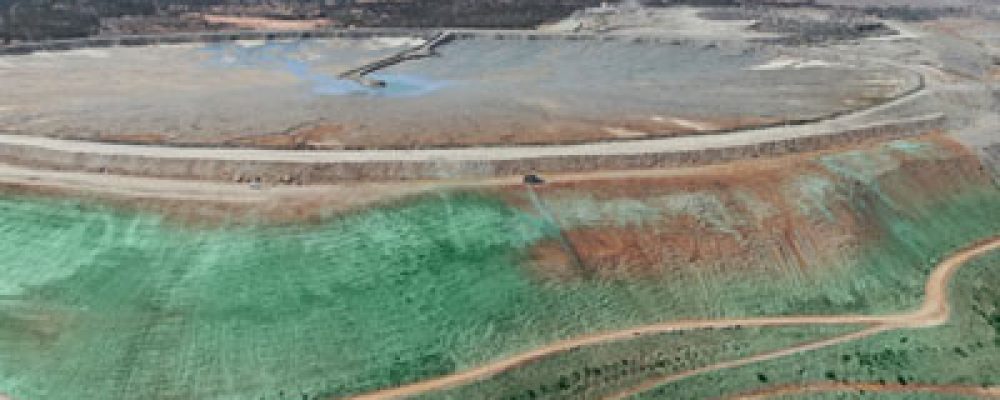

The structure of an open-pit mine is designed for both efficiency and safety, consisting of two main parts: the incline section and the flat part. The incline section of the mine wall, known as the batter, plays a critical role in the mine’s overall stability. It is engineered at a specific angle to prevent landslides and facilitate controlled water drainage from the pit, which is essential for operational efficiency, safety and environmental protection. The flat part, referred to as the bench or berm, is essentially a step created in the mine to help with the extraction process.

Benches provide a safe platform for operations, including drilling, blasting and material removal, and they also help to manage the overall depth of the mine, allowing for efficient access to the various ore layers. The strategic design of batters and benches, adhering to geotechnical engineering principles, ensures that open-pit mining can be conducted safely and sustainably.

Minerals and Resources Extracted

Open-pit mining is versatile in its application, allowing for the extraction of a wide range of minerals and resources essential for various industries worldwide. Some of the common materials extracted include:

- Bitumen: used in road construction and waterproofing

- Clay: crucial for brick, ceramic and cement production

- Coal: a vital energy source

- Copper and Gold: sought after for their use in electrical wiring, jewellery and as investment commodities

- Diamonds: both for industrial applications and as gemstones

- Iron ore: fundamental to the steel-making industry

- Granite, Gritstone and Gypsum: pivotal in construction for making countertops, road aggregate and drywall.

- Gravel and Bedrock: serve as essential aggregates for construction and infrastructure projects.

Post-Operational Environmental Concerns in Open Pit Mining

While mining is a significant source of minerals and metals, it’s equally important to address the environmental concerns that arise post-operation. Fortunately, with technological advancements and comprehensive management strategies, mitigating these impacts is increasingly feasible.

Habitat fragmentation: One of the primary concerns following open pit mining operations is habitat fragmentation. This process can disrupt local ecosystems, affecting biodiversity. However, through careful planning and rehabilitation efforts, mining companies can restore these areas.

Soil erosion and degradation: Soil erosion and degradation are notable concerns following the cessation of mining activities. However, the industry has adopted various soil management techniques to combat these effects. The use of cover crops and mulches to protect exposed soil surfaces significantly reduces erosion, while the incorporation of organic matter improves soil structure and fertility.

Disruption of hydrological systems: The alteration of hydrological systems is another concern associated with open pit mining. However, through the application of advanced hydrological models and water management practices, it’s possible to restore and even improve water systems in post-mining areas.

Air pollution: Air pollution, particularly dust and emissions from machinery, is an inevitable byproduct of mining operations. Nonetheless, the implementation of dust suppression techniques such as water sprays and the encapsulation of dust-producing operations can significantly reduce air pollution.

Governmental Policy in Mine Rehabilitation and Closure Planning

Governmental involvement plays an important role in overseeing and ensuring the effective rehabilitation of mine sites post-operation. Through regulatory frameworks and legislation, governments set the standards and requirements for mining companies to follow in order to mitigate environmental impacts. Key aspects of these policies focus on the comprehensive planning for mine closure, even before mining activities commence. This planning involves detailed strategies for land restoration, waste management and the safeguarding of water quality to prevent contamination.

Furthermore, governments often require mining companies to provide financial guarantees in the form of bonds or assurance funds. These financial instruments ensure that funds are available for rehabilitation activities, even in cases where a company might fail to fulfil its obligations. By enforcing such policies, governments aim to prevent the abandonment of mines without proper closure, thereby protecting the environment and communities from long-term adverse effects. These regulations also encourage sustainable mining practices, ensuring that mineral extraction does not come at the cost of environmental degradation or public health.

Additional Justifications for Rehabilitating Open-Pit Mining Sites

Rehabilitating open-pit mining sites extends far beyond mere compliance with government policies or laws. While legal obligations play a crucial role in ensuring that mining companies undertake rehabilitation efforts, the importance of these activities transcends regulatory adherence. Rehabilitating mine sites is vital for environmental sustainability, community well-being and even for the mining industry’s long-term viability.

Below are key areas where rehabilitation efforts can make a significant difference.

Improvement of Soil Quality

The restoration of soil quality at former mining sites is essential for several reasons. Firstly, it enables the land to be used again for agricultural purposes, supporting local food security and economic activities. Healthy, nutrient-rich soil is the foundation of robust ecosystems, supporting plant, animal and microbial life. Through techniques such as the addition of organic matter, phytoremediation (using plants to absorb or break down pollutants) and careful management of soil erosion, rehabilitated lands can become productive once more. This not only helps in carbon sequestration but also in preserving biodiversity.

Management of Water Resources

Mining operations can significantly alter the natural water balance and quality in an area. Effective rehabilitation efforts focus on restoring or creating new water management systems that can support local ecosystems and communities. This includes the treatment of contaminated water, the reconstruction of natural waterways and the creation of artificial lakes that can serve recreational or conservation purposes. Proper management of water resources post-mining ensures that communities have access to clean water while also supporting aquatic life, thereby contributing to the overall health of the ecosystem.

Control of Air Quality

Dust and emissions from mining operations can have a detrimental effect on air quality, affecting both environmental health and human well-being. Rehabilitation work plays a critical role in mitigating these impacts through the revegetation of mined areas. Vegetation acts as a natural dust barrier, reducing the amount of dust carried by the wind. Additionally, green spaces can help absorb pollutants, improving air quality over time. Efforts to control air quality through rehabilitation also include monitoring and managing any residual emissions from closed sites, ensuring they do not pose a risk to nearby communities or ecosystems.

Traditional Approaches to Mine Site Rehabilitation and Protection

The rehabilitation and protection of mine sites are critical steps in ensuring the environmental impacts of mining are effectively managed and mitigated. Traditional approaches in this area have been developed and refined over the years, focusing on restoring ecological balance and minimising the long-term environmental footprint of mining activities.

These methods include:

Soil excavation and replacement: Soil excavation and replacement is a direct and effective strategy for dealing with soil contamination at mine sites. This method involves the removal of contaminated soil and its substitution with clean, uncontaminated soil from another location.

Bioremediation: Bioremediation leverages the natural processes of living organisms, primarily microbes, to detoxify polluted environments. These microorganisms metabolise contaminants in the soil or water, breaking them down into less harmful substances. The application of bioremediation in mine site rehabilitation can be tailored to specific pollutants, making it a versatile and environmentally friendly approach. It’s especially effective for organic contaminants and certain metals, facilitating the natural recovery of ecosystems.

Water treatment systems: Implementing traditional water treatment systems is crucial to mitigate the after-effects of mining. Techniques include the neutralisation of acidic water, filtration systems to remove particulate matter and chemical treatments to precipitate and remove dissolved metals.

Phytoremediation: Phytoremediation is a green technology that uses plants to clean up soil, air and water contaminated with hazardous contaminants. Certain plants, known as hyperaccumulators, have the ability to absorb and concentrate metals from the soil in their biomass. This method not only removes contaminants but also restores the vegetative cover, reducing erosion and improving the aesthetic and ecological value of the site.

Our Sustainable Solutions to Open Pit Mine Sites Rehabilitation

Erizon is committed to transforming the rehabilitation of open-pit mine sites with sustainable environmental solutions. Our expertise and innovative technologies focus on restoring ecological balance, fostering rapid vegetation growth and securing the long-term sustainability of these sites.

These are the solutions we implement:

Hydroseeding

Our hydroseeding service is at the forefront of revegetation techniques, offering a cost-effective and efficient solution for establishing vegetation on mine sites. By combining seed, mulch, fertilisers and water into a homogenous slurry, we can promote rapid plant growth over large areas. This method is not only effective in soil stabilisation but also enhances the aesthetic appeal of the landscape.

Hydromulching

Erizon’s hydromulching services showcase advanced erosion control and vegetation establishment technologies with our EnviroLoc Airfield®, EnviroSprout HGM® and EnviroLoc® BFM products. These pioneering solutions create a protective soil layer that boosts moisture retention, providing essential nutrients for seed germination and plant growth.

Soil Stabilisation

Soil stabilisation is crucial for the successful rehabilitation of mine sites. Our EnviroSoil® Biotic Soil Amendment is a topsoil alternative that revitalises nutrient-depleted soils, enhancing their ability to support healthy plant life. This product is an integral part of our soil stabilisation efforts, ensuring that vegetation can thrive in previously barren areas.

Dust Suppression

Effective dust suppression is essential for maintaining air quality and minimising the environmental impact of mine sites. Erizon offers comprehensive dust control solutions designed to significantly reduce airborne particles and ensure compliance with environmental regulations.

Erosion Control

Erosion control is vital for protecting soil resources and preventing sediment runoff. At Erizon, we employ a range of methods tailored to the specific needs of each site, ensuring effective long-term erosion control. Our solutions include both physical barriers and vegetation-based approaches to stabilise the soil and promote ecological recovery.

Erizon’s Process to Batter Management

With our expertise in environmental solutions, Erizon plays a significant role in the sustainable management of batters in open-pit mining. Here’s how:

Erosion control in an active mine site: For operational sites with active mining, Erizon’s EcoArmour® offers an innovative solution. This erosion control product is a flexible membrane applied by spray, bonding to soil or rock surfaces to create a resilient layer that withstands weathering and erosion. Particularly valuable in areas prone to disruptions and heavy rainfall, it efficiently curbs soil erosion and sediment runoff.

Rehabilitation during or after mine closure: Post-mining, the attention turns to rehabilitating the slopes to facilitate their seamless integration with the natural surroundings. Erizon utilises a range of techniques to improve soil quality and fertility, such as hydroseeding, revegetation and soil amendments. These methods stabilise the slopes and foster the growth of indigenous flora, thereby supporting ecosystem recovery.

Long-term stability and monitoring: Beyond immediate stabilisation, Erizon ensures the long-term resilience of these structures through continuous monitoring and maintenance. This includes assessing vegetation health, soil stability and the effectiveness of erosion control measures.

Achieve Viability and Sustainability in Open Pit Mining

Erizon’s comprehensive suite of environmental solutions empowers mining companies to achieve the viability and sustainability of their open-pit mine sites. Through our innovative hydroseeding, hydromulching, soil stabilisation, dust suppression and erosion control services, we are committed to restoring the ecological integrity of mined landscapes.

Our approach not only addresses the immediate environmental challenges but also lays the foundation for a sustainable future, ensuring that former mine sites can be transformed into thriving ecosystems or productive lands. With Erizon, the path towards environmentally responsible and sustainable mining practices is clear.

Explore Erizon’s tailored solutions for open pit mining. Find out why partnering with us today is the smart decision!