Mining stockpile management strikes a delicate balance between resource utilisation, environmental responsibility and operational efficiency. It is an often overlooked but critical aspect of mining operations that has far-reaching implications on environmental health, resource conservation and the bottom line of mining companies.

This article will delve into strategies that can help optimise mining stockpile management, reduce the environmental footprint and enhance the overall efficiency of mining operations.

Stockpiling In The Mining Industry

Stockpiling refers to the controlled storage of mined materials—such as ores, waste rock or overburden—in designated areas, commonly known as stockpiles. In the mining industry, stockpiling is an indispensable process, serving as the bridge between extraction and processing or distribution.

Why Is There A Need To Manage Stockpiles?

The mining industry is subject to stringent regulations when it comes to stockpile management. This ensures that environmental protection remains a priority, as well as the health and safety of miners. Poorly managed stockpiles can cause hazardous conditions or environmental degradation, which is why mining organisations are encouraged to implement effective stockpile management strategies.

Negative Effects From Stockpile Mismanagement

From an operational perspective, poorly managed stockpiles can result in inefficiencies and increased costs. For example, if stockpile volumes are not accurately tracked and if materials are not properly segregated, this can lead to a loss of valuable resources and higher processing costs.

Moreover, mismanaged stockpiles can also pose safety and environmental risks such as:

Dust And Smoke Emission

Stockpile management must include measures to reduce dust and smoke emission. If unmanaged, these particles can be a source of air pollution, which can lead to respiratory issues among miners and those living in nearby areas.

Loss Of Biodiversity

Poorly managed stockpiles can also lead to the disruption of ecosystems and the loss of biodiversity. This occurs when toxic materials seep into water sources or accumulate in soils, leading to soil acidification and contamination that can be detrimental for flora and fauna.

Soil And Water Pollution

Stockpile management should also include strategies to prevent soil and water pollution. Soil and water can be contaminated by heavy metals, organic compounds, toxic chemicals or other materials used in the mining process. If left unchecked, these pollutants can accumulate over time in the environment and pose a serious threat to human health.

Regulatory And Environmental Practices In Managing Stockpiles

To ensure responsible mining practices, a multitude of regulations have been put in place that mining companies must adhere to. These regulations not only focus on minimising environmental impact but also on promoting resource conservation and safe operational practices.

Regulatory Framework

Mining companies are required to submit their stockpile management plans to relevant authorities for approval. These plans must include measures to reduce dust and smoke emission, minimise the impact of stockpiles on nearby ecosystems and prevent soil and water contamination.

Waste Management

Mining companies must also ensure that their stockpiles are properly managed and that all waste materials are disposed of in an environmentally-friendly manner. This includes the segregation of hazardous and non-hazardous waste as well as proper disposal techniques for each type.

Community Engagement

In addition to complying with environmental regulations, mining companies must also engage the surrounding communities in their stockpile management practices. This can be done through regular consultations and community outreach initiatives that aim to create a sense of ownership over the process.

Conventional Stockpile Dust Management Methods

In recent years, the advent of modern technologies has greatly enhanced the efficiency and effectiveness of stockpile management in the mining industry.

Some of the conventional methods used for dust management include:

Sprinkler Systems

Water sprays are used to suppress dust particles in stockpiles by wetting the material and creating a barrier between it and the air. This method is effective but can be costly, due to its high water consumption.

Effective management of stockpile dust requires a delicate balance between efficient water usage and sustainable practices. This careful equilibrium is crucial for businesses seeking both economic and environmental sustainability.

Wetting Agents And Binders

Wetting agents and binders are chemical substances that can be added to stockpiles in order to reduce dust emission. These products effectively reduce the amount of dust released into the air, though they need to be monitored regularly for their effectiveness.

Wind Fencing And Barriers

Wind fences or covers can also be used to contain dust. However, this method may not be suitable for all types of stockpiles as it can increase the risk of fire hazard due to the changes in wind pattern caused by wind barriers.

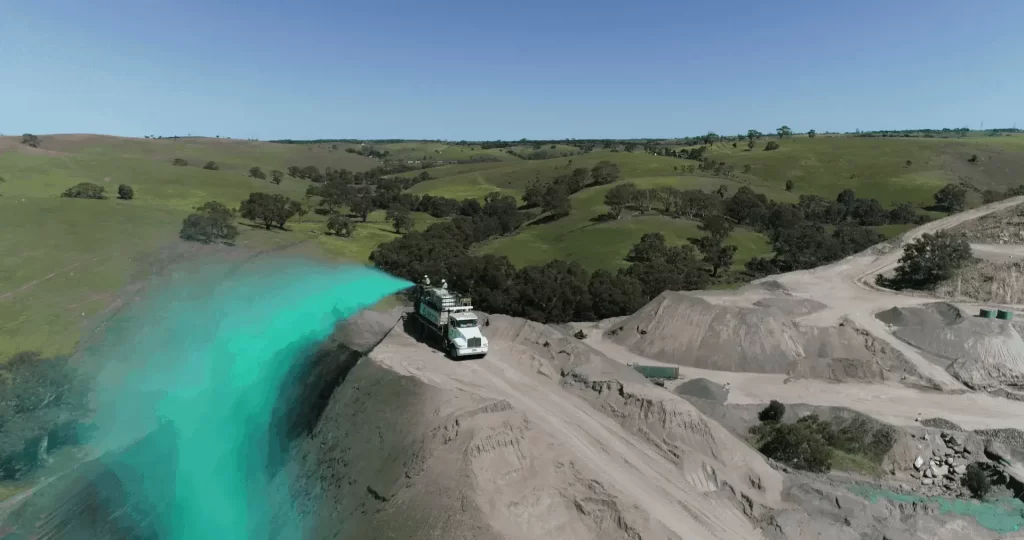

Erizon’s Dust And Erosion Control Solution To Manage Stockpiles

We have a deep understanding of the importance of reducing stockpile dust. We are not only confident in our product, but we also back it up with a supply apply guarantee. We are proud holders of certifications for safety, environmental management systems, and quality management systems.

Some of the methods we employ to manage stockpile dust and erosion include:

SuppressX

SuppressX is a versatile solution suitable for various substrates such as tailings, ash dams and stockpiles. Its flexible crust consists of microscopic cross-linked superabsorbent polymers that effectively bind fine particles, ensuring rapid and efficient dust suppression.

Elevate Mining Operations With Proven Stockpile Management

The management of stockpiles in the mining industry is of paramount importance, not only for operational efficiency and cost-effectiveness but also for adhering to regulatory measures and minimising environmental impact.

With our advanced solutions, we can offer innovative and sustainable approaches to dust and erosion control, contributing to safer, cleaner and more responsible mining practices.

These solutions meet the needs of the industry with our commitment to preserving the environment, ensuring that mining activities can coexist with our shared responsibility towards ecological conservation.

Take control of dust emissions and elevate your stockpile management. Contact our Environmental Advisor for more information.