Construction sites, mines, and other industrial facilities frequently include stockpiles. Before they are processed or delivered, raw materials like coal, ore, or sand are stored this way. However, processing these materials can produce a lot of dust, which can be harmful to the environment and to people’s health. The significance of dust control in stockpiles and several approaches to achieving effective management will be discussed in this blog.

Why is Dust Control Important for Stockpile management?

The environment and human health may be negatively impacted by dust emissions from stockpiles in a number of ways. Long-distance air pollution from tiny dust particles can degrade the air quality in adjacent towns. Breathing issues can occur from inhaling these particles, especially in people who have illnesses like asthma or chronic obstructive lung disease (COPD). In addition, dust emissions can also affect road visibility, which could result in traffic accidents.

Additionally, dust emissions may harm the ecosystem by contaminating the soil and water. The development and quality of crops nearby can be damaged by fine dust particles that land on them. They can deteriorate the quality of water used for agriculture and drinking by contaminating groundwater and surface water bodies.

Methods for Dust Control in Stockpile

To reduce the impact of dust emissions from stockpiles, several methods can be used. The most commonly used methods are discussed below.

Wetting The Surface

Reducing dust emissions can be done easily and effectively by wetting the stockpile’s surface. The amount of dust released into the air is decreased thanks to water’s ability to bind the particles together. To get the best results, use this strategy with other dust suppression techniques such as chemical treatments. It may, however, have a number of disadvantages. For instance, it needs a steady supply of water, which can be difficult in places with few water resources. Additionally, if the water is not equally distributed throughout the stockpile, pockets of dry material may form that are still capable of producing dust. In addition, the material may get even dryer if the water evaporates, which would increase the likelihood of dust emissions. Also, the water may make the substance heavier and more compact, which will make it more challenging to transport and manage. The material’s quality and value may occasionally be diminished as a result of using water.

Covering the Stockpile

Covering the stockpile with a tarp or other type of cover can significantly reduce dust emissions. This method works by limiting the amount of air that reaches the surface of the stock pile, reducing the amount of dust that is released into the air. The cover should be made of a durable material that can withstand harsh weather conditions and prevent dust from escaping. However, there are potential issues with this method. Covering stockpiles to control dust emissions can be expensive due to the cost of cover materials and installation. Maintenance can also be a challenge as regular inspections are needed to keep the cover in good condition, and repairs or replacements may be required if it is damaged.

Accessibility can also be limited as the cover restricts access to the material, causing potential delays in processing and shipping. Moisture buildup can also occur if the cover is not designed or installed properly, leading to the degradation of the material. In areas with harsh weather conditions, the cover must be designed to withstand them or may need to be removed during inclement weather, making it less effective as a dust control measure. Alternative methods, such as wetting the surface, chemical treatments, and water sprays, may be more effective in certain situations.

Windbreaks And Fencing

Dust emissions from stockpiles can be lessened with fencing and windbreaks. The amount of dust released into the air can be decreased by rerouting the wind and erecting a barrier around the stockpile. In addition to preventing access to the stockpile, fencing can assist in lessening the disturbed dust and the risk of accidents. Although this can be a useful technique for reducing dust on stockpiles, several drawbacks must be considered.

One limitation is that they only provide protection from wind-borne dust, which makes it a limited solution. Additionally, fencing and windbreaks can be expensive to construct and maintain, especially if they need to be designed to withstand strong winds or harsh weather conditions. Another limitation is that they may take up valuable space that could otherwise be used for storage or other purposes, reducing the efficiency and profitability of a stockpile site. Moreover, fencing and windbreaks may only be suitable for some stockpile sites, such as areas with high wind speeds or limited space for structures. These limitations should be carefully evaluated before deciding whether fencing and windbreaks are the best options for suppressing dust on a specific stockpile.

Chemical & Polymer-Based Treatments

Chemical treatments involve the application of a dust suppression agent, such as a surfactant, to the surface of the stockpile. The agent helps to bind the particles together, reducing the amount of dust that is released into the air. Some typical surfactants used for dust suppression include sodium silicates and polysaccharides. The effectiveness of sodium silicates and polysaccharides versus polymer-based solutions for stockpile dust suppression will depend on various factors, such as the type and properties of the material being stored, the weather conditions in the area, and the specific requirements for dust control.

Sodium silicates and polysaccharides are commonly used for dust suppression because they are biodegradable and relatively safe for the environment.

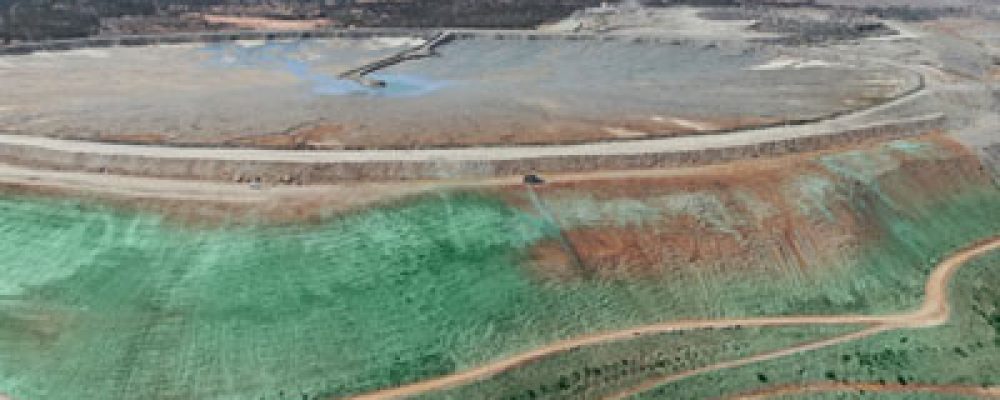

Polymer-based dust suppression solutions are a good option for protecting stockpiles due to their ability to form a dense, permeable layer over the material’s surface. This layer effectively prevents dust from becoming airborne, providing efficient and long-lasting dust control. Additionally, polymer-based solutions are versatile and can be used in various materials, including coal, aggregate, and soil. They require low maintenance and can provide effective dust control at a lower cost than other methods, such as covering the stockpile or installing automatic dust suppression systems. These benefits make polymer-based dust suppression solutions an attractive option for stockpile managers looking to protect their stockpiles from dust emissions.

Conclusion

Controlling dust emissions from stockpiles is important for protecting the environment and human health. Several methods can be used, such as wetting the stockpile surface, covering it, using fencing and windbreaks, or applying chemical or polymer-based treatments.

Among these polymer-based treatments is a high-performance solution from Erizon, which offers a durable, longer-lasting, and cost-efficient solution to controlling dust emissions. This product effectively binds particles together and reduces dust emissions, making it a suitable option for controlling dust on stockpiles. It is recommended to carefully evaluate each method’s limitations and specific requirements before deciding on the best solution for controlling dust in stockpiles.

For more information about effective dust suppression for your site-specific needs, contact our dust environmental advisors today for a free, no-obligation quote.