Construction sites, mines, and other industrial facilities frequently include stockpiles to store raw materials, such as coal, ore, and sand, before they are processed or delivered.

However, processing these materials can produce a lot of dust, which can harm the environment and people’s health. Stockpile dust control is an essential aspect of stockpile management and involves implementing strategies and technologies to reduce or eliminate dust emissions from these piles of materials. But what is a stockpile and why is stockpile dust control so important?

What Is Stockpile and Where Does it Come From?

A stockpile is a pile of raw materials or waste products stored in a designated area before being processed, transported, or disposed of. These stockpiles can be part of various industries, including mining, construction, agriculture, and demolition.

One of the leading causes of dust in stockpiles is wind erosion. As these piles are often left uncovered, strong winds can easily blow and disperse the dust particles into the air. Other causes include handling and movement of materials, crushing or grinding processes, and natural elements such as rainfall, which can create mud and dust when mixed with stockpile materials.

Why Is Stockpile Dust Suppression Important?

If your facility has stockpiles, then you must implement proper dust control measures for the following reasons:

- Compliance and legal obligations: Many countries have established regulations and guidelines for controlling dust emissions, especially in industries where stockpiles are prevalent. Failure to comply with these regulations can lead to fines, legal consequences, and damage to a company’s reputation.

- Health, safety, and air quality: Stockpile dust emissions can travel long distances through the air, leading to degraded air quality in surrounding areas. Inhaling dust particles can also cause breathing issues, especially for those with existing respiratory illnesses such as asthma or COPD (chronic obstructive pulmonary disease). Additionally, dust can reduce road visibility and increase the risk of traffic accidents. Finally, dust emissions can have a detrimental impact on the ecosystem. Dust can contaminate nearby soil and water, affecting the health of plants and animals in the surrounding area. This can lead to decreased crop development and quality as well as contamination of groundwater and surface water bodies used for agriculture and drinking purposes.

- Operational efficiency: Excessive dust can cause blockages in equipment and machinery, leading to unplanned downtime and costly repairs. It can also affect worker productivity and increase maintenance costs. Proper stockpile dust control can help improve operational efficiency, reduce downtime, and save money in the long run.

- Cost savings: By reducing dust emissions, companies can avoid costly fines and legal consequences, minimise equipment maintenance and repair costs, and improve worker productivity. Additionally, effective dust suppression methods can help preserve the quality of stockpile materials, leading to higher profits when these materials are sold.

Methods for Dust Control in Stockpiles

Several strategies can be used to reduce the impact of dust emissions from stockpiles. The following are some of the most commonly used methods.

Wetting the Surface

One easy way to reduce dust emissions is by wetting the surface of your stockpile. Using water to wet the surface helps to bind the particles together, preventing them from becoming airborne. This method is effective and easy to implement, but it does have some drawbacks:

- Water may be limited in some areas, which can make this method impractical.

- If the water is not evenly distributed throughout the stockpile, some pockets of dry material may remain, which are still capable of producing dust.

- The material may get even drier if the water evaporates, increasing the likelihood of dust emissions.

- Adding water to your stockpile may make the substance heavier and more compact, making it more challenging to transport and manage.

- In some cases, the material’s quality and value could be diminished as a result of using water.

To get the best results, use this strategy with other dust suppression techniques, such as chemical treatments.

Covering the Stockpile

Covering the stockpile with a cover such as a tarp will limit the amount of dust released into the air. The cover should be made out of a durable material that can withstand harsh weather conditions and prevent dust from escaping. However, there are potential issues with this method:

- Covering stockpiles to control dust emissions can be expensive due to the cost of cover materials and installation.

- Maintenance can be challenging, as regular inspections are needed to keep the cover in good condition, and repairs or replacements may be required if it is damaged.

- Accessibility can also be limited as the cover restricts access to the material, causing potential delays in processing and shipping.

- Moisture buildup can occur if the cover is not designed or installed correctly, leading to the degradation of the material.

- In areas with harsh weather conditions, the cover must be designed to withstand them or may need to be removed during inclement weather, making it less effective as a dust control measure.

Alternative methods like wetting the surface, chemical treatments and water sprays may be more effective in certain situations.

Windbreaks and Fencing

The amount of dust released into the air can be decreased by erecting a barrier around the stockpile and rerouting the wind. This can be done using windbreaks, which can be natural or artificial structures that reduce the speed of wind, or fencing, which blocks the wind entirely.

In addition to preventing access to the stockpile, fencing can assist in reducing the disturbed dust and the risk of accidents. Although this can be a valuable technique for reducing dust on stockpiles, several drawbacks must be considered:

- Barriers only provide protection from wind-borne dust, which makes them a limited solution.

- Fencing and windbreaks can be expensive to construct and maintain, especially if they need to be designed to withstand strong winds or harsh weather conditions.

- They may take up valuable space that could otherwise be used for storage or other purposes, reducing the efficiency and profitability of a stockpile site.

- Fencing and windbreaks may only be suitable for some stockpile sites, such as areas with high wind speeds or limited space for structures.

These limitations should be carefully evaluated before deciding whether fencing and windbreaks are the best options for suppressing dust on a specific stockpile.

Chemical and Polymer-Based Treatments

Another alternative for dust control is using chemical or polymer-based treatments. These solutions can be sprayed directly onto the stockpile or added to the material during processing to bind particles and prevent them from becoming airborne.

Chemical treatments involve the application of a dust suppression agent, such as a surfactant, to the surface of the stockpile. This agent helps to bind the particles together, reducing the amount of dust that is released into the air. Some typical surfactants used for dust suppression include sodium silicates and polysaccharides, which are environmentally friendly and biodegradable.

Polymers are synthetic chemical compounds that can absorb water, forming a gel-like substance. These polymers can either be applied directly to the surface of the stockpile or mixed with water and sprayed onto the material. They typically form a dense, permeable layer on the surface of the stockpile, preventing dust emissions and helping to stabilise the material. Additionally, polymer-based solutions are versatile and can be used for various materials, including coal, aggregate, and soil.

Polymer-based treatments require low maintenance and can provide effective dust control at a lower cost than other methods, such as covering the stockpile or installing automatic dust suppression systems. These benefits make polymer-based dust suppression solutions an attractive option for stockpile managers looking to protect their stockpiles from dust emissions.

The effectiveness of sodium silicates and polysaccharides versus polymer-based solutions for stockpile dust suppression will depend on various factors, such as the type and properties of the material being stored, the weather conditions in the area and the specific requirements for dust control.

We Offer Environmentally-Compliant Dust Suppression Solutions

At Erizon, we are committed to providing environmentally compliant solutions for dust control. We are a leading provider of dust suppression solutions for a wide range of industries, including construction, mining, and infrastructure development.

Our products and services are carefully designed to reduce the release of dust into the air without causing harm to the environment or nearby communities. We understand that each stockpile site is unique, and we work closely with all of our clients to develop customised solutions that meet their specific requirements.

The following are some key components of our environmentally compliant dust suppression solutions:

- SuppressX: SuppressX is an effective and versatile dust suppression solution for non-trafficked areas. It creates a protective barrier over the substrate, preventing dust lift-off and resisting wind and rain. With an ultra-low concentration, it effectively suppresses dust without altering the composition of the underlying material. The translucent solution can be diluted with water and dyed before being sprayed onto the surface, ensuring even distribution. It can be applied using standard spraying equipment, water carts and tankers.

- HydroBond: HydroBond is an environmentally friendly solution consisting of a blend of polymers and additives that is effective for suppressing dust. It also promotes faster vegetation growth by forming a permeable biodegradable crust on the surface, retaining water and essential nutrients. This results in more efficient revegetation and erosion control, making it a superior choice for dust suppression. Its open matrix structure allows air and water to penetrate while protecting seeds from external factors.

- RoadBond: RoadBond is a non-corrosive, environmentally-friendly dust suppressant solution that eliminates dust on unsealed road surfaces, improves road stability, reduces maintenance costs and minimises tyre wear. It consists of super-absorbent polymers that create a durable layer resistant to traffic wear, wind erosion, and water impact. The chemical innovation behind this product allows for safe and effective dust suppression for up to six months, making it suitable for harsh conditions found in mining, resources, and infrastructure industries.

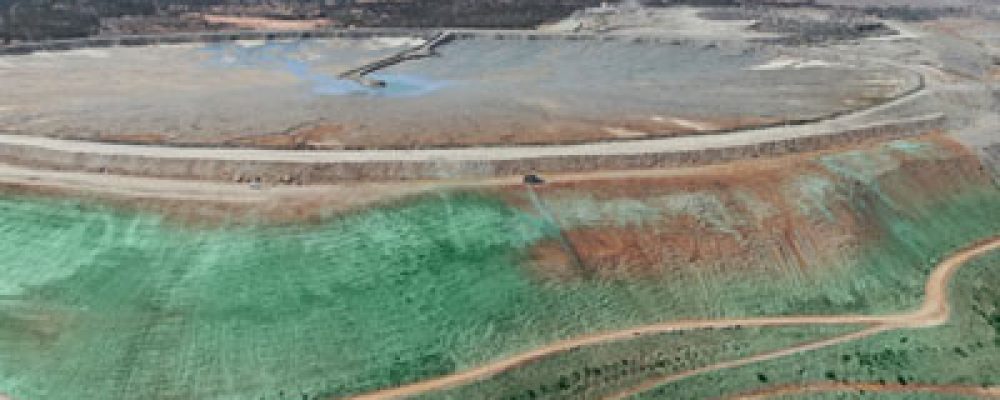

- FibreLoc: FibreLoc is an environmentally friendly dust suppression product scientifically designed to withstand harsh conditions where traditional polymer solutions may not be suitable. Made from interlocking organic wood fibres and sustainable binders, it forms a flexible blanket that can resist high salinity levels, making it ideal for use in tailing storage facilities. The unique design also allows FibreLoc to re-establish itself if damaged by shifting substrates, making it perfect for use on uneven terrains. Additionally, the wood fibres act as a catchment zone to trap dust caused by strong winds and can support plant growth by providing an ideal environment for seeds and fertilisers.

Why Work with Us in Suppressing Stockpile Dust

Erizon is a trusted and experienced industry leader in large-scale revegetation, rehabilitation, dust suppression, and erosion control projects across Australia. With over 25 years of experience and a proven track record of delivering successful solutions in even the most challenging climates, we are the go-to choice for clients in various industries.

At Erizon, our scientific approach and continuous innovation are the driving forces behind our success. We are dedicated to finding new and improved methods and technologies to help our clients achieve their goals while minimising environmental impact.

We prioritise safety in all aspects of our work and have extensive certifications for safety, environmental and quality management systems that align with ISO and Australian Standards. Our affiliations with organisations such as the International Erosion Control Association (IECA) also demonstrate our commitment to staying up-to-date with industry standards and best practices.

Our core values of safety, innovation, excellence, efficiency, integrity and teamwork guide us in everything we do. We believe in providing great value to our clients and ensuring the success of every project we undertake. Whether it’s dust control for a mining site or erosion control for an infrastructure project, we have the expertise and resources to deliver effective solutions.

Let Erizon Help Prevent Dust Pile-Up in the Air

Controlling dust emissions from stockpiles is vital for protecting both the environment and human health. Several methods can be used, such as wetting the stockpile surface, covering it, using fencing and windbreaks, or applying chemical or polymer-based treatments.

Here at Erizon, our high-performance polymer-based treatment is a durable, longer-lasting, and cost-efficient solution to controlling dust emissions. This product effectively binds particles together and reduces dust emissions, making it a suitable option for controlling dust on stockpiles. It is recommended to carefully evaluate each method’s limitations and specific requirements before deciding on the best solution for controlling dust in stockpiles.

For more information about effective dust suppression for your site-specific needs, contact our environmental dust advisors today for a free, no-obligation quote.